¶ FHL-LD19P Lidar

¶ Product Description

Please note that this article is being updated and some content may be missing or incomplete.

LD19 is mainly composed of laser ranging core, wireless transmission unit, wireless communication unit, angle measurement unit, motor drive unit and mechanical shell.

中文资料:https://wiki.youyeetoo.cn/zh/LD19

There are three versions in Youyeetoo's LD19 series, which are FHL-LD19, FHL-LD19P, and FHL-LD19 Plus respectively.

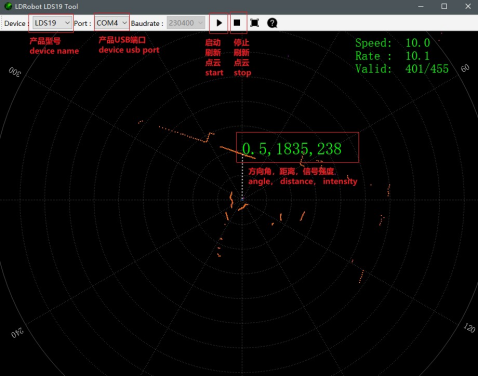

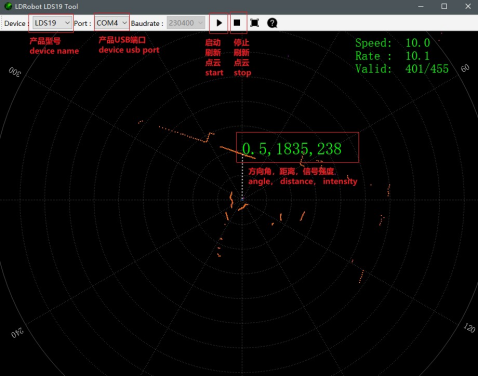

The diagram of the environmental scan formed by LD19 point cloud data is shown below:

The product is mainly suitable for the navigation and obstacle avoidance of robots (e.g. floor mopping robots and service robots) by performing a 360° scan of the indoor layout and building a map so that a walking path can be planned. It is also suitable for robotics education and research, etc.

¶ Difference

| Model | FHL-LD19P | FHL-LD19(Discontinue) | FHL-LD19 Plus (New) |

|---|---|---|---|

| Parameter/Feature | STL-19P | LD19 | STL-27L |

| Product Overview | DTOF technology, 5000 measurements per second, suitable for robot navigation and obstacle avoidance. | DTOF technology, 4500 measurements per second, suitable for robot navigation and obstacle avoidance. | DTOF technology, 21600 measurements per second, suitable for commercial service robot navigation and obstacle avoidance. |

| Measuring Range | 0.03~12m (white target), 0.03~8m (black target) | 0.02~12m (70% reflectivity) | 0.03~25m (white target), 0.03~10m (black target) |

| Measuring Accuracy | |||

| 0.03~0.5m | ±10mm (average error), 2mm (STD) | - | ±15mm (average error), 5mm (STD) |

| 0.5~2m | ±20mm (average error), 4mm (STD) | - | ±20mm (average error), 15mm (STD) |

| 2m~12m | ±30mm (average error), 15mm (STD) | ±45mm (average error) | ±30mm (average error), 25mm (STD) |

| Scanning Frequency | 6~13Hz (externally controlled by PWM) | 5~13Hz (externally controlled by PWM) | 6~13Hz (externally controlled by PWM) |

| Measuring Frequency | 5000Hz | 4500Hz | 21600Hz |

| Dimensions | 54.00×46.29×34.80mm | 38.59×38.59×33.50mm | 54.00×46.29×34.80mm |

| Weight | Approximately 45g | Approximately 47g | 45g |

| PWM Speed Control | Internal and external speed control supported | Internal and external speed control supported | Internal and external speed control supported |

| Glass Detection | Supported | Not specified | Supported |

| Environmental Light Resistance | 60Klux | 30Klux | 60Klux |

| Lifetime | 10,000 hours | 10,000 hours | 10,000 hours |

| Safety Standards | Class I laser safety standard | Class I laser safety standard | Class I laser safety standard |

How to Read the Table:

Measuring Accuracy: Lists the accuracy metrics for different distance ranges.

PWM Speed Control: Supports motor speed control via PWM signals, with external control requiring specific PWM input signals.

Environmental Light Resistance: Indicates the sensor's capability to function in strong ambient light conditions.

Lifetime: The expected lifespan of the product under normal use conditions.

Safety Standards: All products meet the Class I laser safety standard, ensuring safety for humans and pets.

¶ Download

If you encounter technical problems, please provide feedback to forum@youyeetoo.com.

-

All source SDK Google Drive

-

Windows Software Google Drive

-

USB Driver Google Drive | Silicon Offical CP210X

-

SDK Google Drive

If LD19 Plus encounters problems with the v3.0.3 SDK, try the v3.0.5 SDK.

¶ Quick Start

Please note that this article is being updated and some content may be missing or incomplete.Feedback: support@youyeetoo.com

¶ Essentials You Need

- A Windows PC

- LD19 lidar devemopment kit (Included Lidar, USB adapter, USB Cable).

- If you want to use it on a Raspberry Pi or MCU, you can choose a bundle with Dupont cables.

¶ Step

- Download the Windows software.The latest version is 3.0.6.

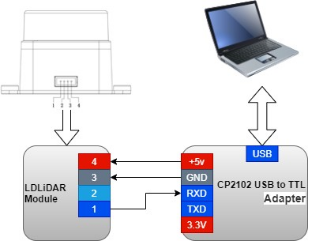

- As shown in the figure, connect the LD19 and the PC.

If it prompts that the USB serial device cannot be recognized, please install the USB driver first.

- Select different device models according to different lidar kits.

| Sensor Model | Device |

|---|---|

| FHL-LD19P | LDS19 |

| FHL-LD19 | LDS06 |

| FHL-LD19 Plus | STL-27L |

More detail, Please check How To Use Kit and linux SDK/ROS/ROS2

¶ How To Use Kit and linux SDK/ROS/ROS2

¶ How to use the assessment tool

¶ Hardware cable connection and description

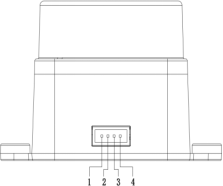

1.LiDAR, wire, USB adapter board, as shown in the following figure:

2.Connection diagram, as shown in the figure below:

3.Or connect directly to the motherboard or MCU.

¶ When Evaluating Products under Windows

-

Necessity of Installation

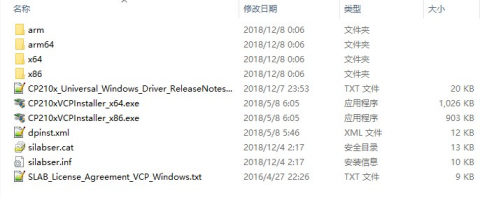

When evaluating products under the Windows system, it is necessary to install the serial port driver for the USB adapter board. The reason is that the USB adapter board in the development kit provided by the company uses the CP2102 USB-to-serial port adapter chip. Its driver can be downloaded from the official website of Silicon Labs: https://www.silabs.com/developers/usb-to-uart-bridge-vcp-drivers -

Driver Installation Steps

- Extract the driver package: Decompress the CP210x_Universal_Windows_Driver driver package.

- Select the version and run the installation program: Execute the.exe file in the driver installation package directory. You need to select X86 (32-bit) or X64 (64-bit) according to your Windows system version.

Reference image:

- Complete the installation: Double-click the.exe file and follow the prompts to complete the installation.

Reference image:

-

Verify the Installation Result

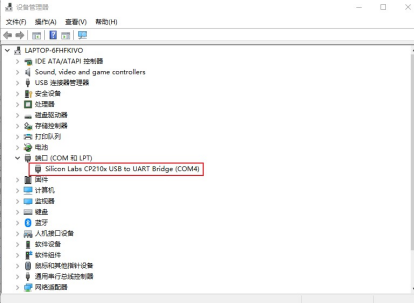

After the installation is complete, connect the USB adapter board in the development kit to your computer. Follow the steps below to verify whether the driver is installed successfully:- Right-click on [My Computer] and select [Properties].

- In the opened [System] interface, select [Device Manager] from the left menu to enter the Device Manager.

- Expand [Ports]. If you can see the serial port number corresponding to the recognized CP2102 USB adapter, it means the driver is installed successfully. For example, in the following figure, it shows COM4.

-

Using

LdsPointCloudViewersoftware under Windows

-

Introduction

LdsPointCloudVieweris a software for real - time point - cloud visualization of product scans, which enables developers to visually observe the scanning renderings conveniently. -

Usage Steps

- Prerequisites: Ensure that the driver of the product's USB adapter board is successfully installed and the product is connected to the USB port of a Windows - system PC.

- Operation Process: Double - click the

LdsPointCloudViewer.exefile, select the corresponding product model and port number, and click the "Start Point - Cloud Refresh" button.

¶ How to use ROS SDK

¶ ROS environment introduction and installation

ROS (Robot Operating System) is an open source meta-operating system for robots and middleware built on Linux. It provides the services expected of an operating system, including hardware abstraction, low-level device control, implementation of commonly used functions, message passing between processes, and package management. It also provides the tools and library functions needed to obtain, compile, write, and run code across computers. For the installation steps of each version of ROS, please refer to the official ROS website:

http://wiki.ros.org/ROS/Installation

The ROS function package of this product supports the following versions and environments:

ROS Kinetic(Ubuntu16.04);

ROS Melodic(Ubuntu18.04);

ROS Noetic(Ubuntu20.04).

¶ Get the source code of the ROS Package

- Check the README.md file for ROS SDK installation instructions.

- Note the file path for the operation

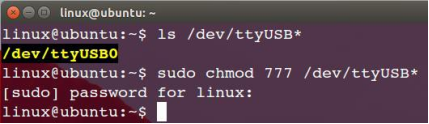

¶ Set device permissions

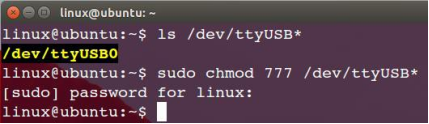

First, connect the lidar to our adapter module (CP2102 adapter), and connect the module to the computer. Then, open a terminal under the ubuntu system and enter ls /dev/ttyUSB* to check whether the serial device is connected. If a serial port device is detected, use the sudo chmod 777 /dev/ttyUSB* command to give it the highest authority, that is, give the file owner, group, and other users read, write and execute permissions, as shown in the following figure.

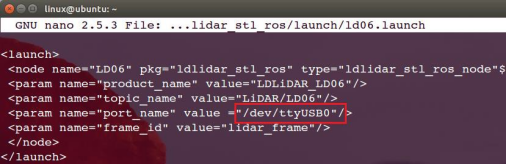

Finally, modify the port_name value in the ld19.launch file in the

~/ldldiar_ros_ws/src/ldlidar_stl_ros/launch/ directory. Take the lidar mounted in the

system as /dev/ttyUSB0 as an example, as shown below.

$ nano ~/ldlidar_ros_ws/src/ldldiar_stl_ros/launch/ld19.launch

Linux nano editor: Ctrl + O saves the edited file; Ctrl + X exits the editing interface.

¶ Build and environment settings

1.Use the catkin compilation system to compile and build the product function package:

$ cd ~/ldlidar_ros_ws

$ catkin_make

2.Function package environment variable settings:

After the compilation is completed, you need to add the relevant files generated by the compilation to the environment variables, so that the ROS environment can recognize them. The execution command is as follows. This command is to temporarily add environment variables to the terminal, which means that if you reopen a new terminal, you also need to re-execute it. The following command.

$ cd ~/ldlidar_ros_ws

$ source devel/setup.bash

In order to never need to execute the above command to add environment variables after reopening the terminal, you can do the following.

$ echo “source ~/ldlidar_ros_ws/devel/setup.bash” >> ~/.bashrc

$ source ~/.bashrc

¶ Run node

Use the roslaunch tool to start the lidar node and execute the following command.

$ roslaunch ldlidar_stl_ros ld19.launch

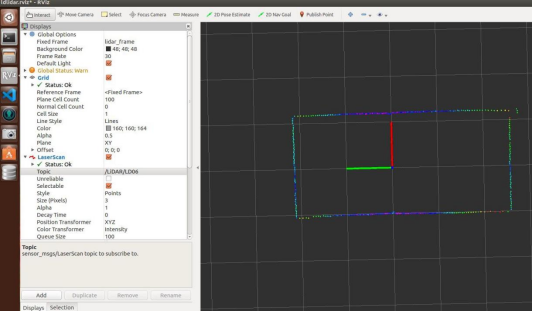

¶ Rviz display LiDAR point cloud

Rviz is a 3D visualization tool in the ROS framework, where lidar data can be displayed. After roslaunch successfully runs the lidar node, open a new terminal (Ctrl+Alt+T) and enter the following command:

$ rosrun rviz rviz

After the interface starts, click file->open->Config in the menu bar of the interface, then select: ldlidar.rviz file in the ~/ldlidar_ros_ws/src/ldlidar_stl_ros/rviz/ directory, open the configuration file ldlidar.rviz, and click LaserScan Select

/LiDAR/LD19 in the Topic.

Since the point cloud data of our lidar product follows the left-handed coordinate system (clockwise), and Rviz shows that the radar point cloud data follows the right-handed coordinate system (counterclockwise), we performed the product point cloud data in the function package source code toLaserScan function. The coordinate system is transformed so that it can display the point cloud normally in Rviz.

¶ How to use ROS2 SDK

¶ ROS2 environment introduction and installation

ROS (Robot Operating System) is an open source meta-operating system for robots and middleware built on Linux. It provides the services expected of an operating system, including hardware abstraction, low-level device control, implementation of commonly used functions, message passing between processes, and package management. It also provides the tools and library functions needed to obtain, compile, write, and run code across computers. The robotics and ROS community has changed a lot since ROS was launched in 2007. The goal of the ROS2 project is to adapt to these changes, leveraging the strengths of ROS1 and improving on the weaknesses. For the installation steps of ROS2, please refer to the official website of ROS2:https://docs.ros.org/en/foxy/Installation.html

The ROS2 function package of this product supports the use of the ROS2 Foxy (Ubuntu20.04) version environment.

¶ Get the source code of ROS2 Package

- Check the README.md file for ROS SDK installation instructions.

- Note the file path for the operation

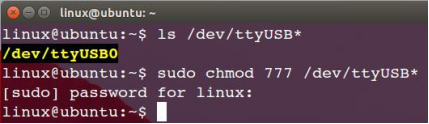

¶ Set device permissions

First, connect the lidar to our adapter module (CP2102 adapter), and connect the module to the computer. Then, open a terminal under the ubuntu system and enter ls /dev/ttyUSB* to check whether the serial device is connected. If a serial port device is detected, use the sudo chmod 777 /dev/ttyUSB* command to give it the highest authority, that is, give the file owner, group, and other users read, write and execute permissions, as shown in the following figure.

Finally, modify the port_name value in the ld19.launch file in the

~/ldldiar_ros_ws/src/ldlidar_stl_ros/launch/ directory. Take the lidar mounted in the

system as /dev/ttyUSB0 as an example, as shown below.

$ nano ~/ldlidar_ros2_ws/src/ldldiar_stl_ros2/launch/ld19.launch.py

Linux nano editor: Ctrl + O saves the edited file; Ctrl + X exits the editing interface.

¶ Build and environment settings

1.Use the catkin compilation system to compile and build the product function package:

$ cd ~/ldlidar_ros2_ws

$ colcon build

2.Function package environment variable settings:

After the compilation is completed, you need to add the relevant files generated by the compilation to the environment variables, so that the ROS environment can recognize them. The execution command is as follows. This command is to temporarily add environment variables to the terminal, which means that if you reopen a new terminal, you also need to re-execute it. The following command.

$ cd ~/ldlidar_ros2_ws

$ source install/setup.bash

In order to never need to execute the above command to add environment variables after reopening the terminal, you can do the following.

$ echo “source ~/ldlidar_ros2_ws/install/setup.bash” >> ~/.bashrc

$ source ~/.bashrc

¶ Run node

Use the roslaunch tool to start the lidar node and execute the following command.

$ ros2 launch ldlidar_stl_ros2 ld19.launch.py

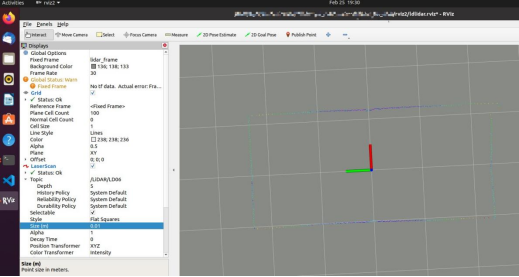

¶ Rviz2 display LiDAR point cloud

Rviz2 is a 3D visualization tool in the ROS2 framework, where lidar data can be displayed. After ros2 launch successfully runs the lidar node, open a new terminal (Ctrl+Alt+T) and enter the following command:

$ rviz2

After the interface is started, click file->open->Config in the menu bar of the interface, and then select: ldlidar.rviz file in the

~/ldlidar_ros2_ws/src/ldlidar_stl_ros2/rviz2/ directory, open the configuration file ldlidar.rviz, and click LaserScan Select /LiDAR/LD19 in the Topic.

Since the point cloud data of our radar product follows the left-handed coordinate system (clockwise), and Rviz2 shows that the lidar point cloud data follows the right-handed coordinate system (counterclockwise), we performed the product point cloud data in the function package source code toLaserScan function. The coordinate system is transformed so that it can display the point cloud normally in Rviz2.

¶ How to use Linux SDK (C/C++)

¶ Get the source code of SDK

- Check the README.md file for ROS SDK installation instructions.

- Note the file path for the operation

¶ Set device permissions

First, connect the lidar to our adapter module (CP2102 adapter), and connect the module to the computer. Then, open a terminal under the ubuntu system andenter ls /dev/ttyUSB* to check whether the serial device is connected. If a serial port device is detected, use the sudo chmod 777 /dev/ttyUSB* command to give it the highest authority, that is, give the file owner,group, and other users read, write and execute permissions, as shown in the following figure.

¶ Build

The source code is coded in C++11 standard C++ language and C99 standard C language. Use CMake, GNU-make, GCC and other tools to compile and build the source code. If you use Ubuntu system without the above tools installed, you can execute the following command to complete the installation.

$ sudo apt-get install build-essential cmake

If the tools indicated above already exist in the system, do the following.

$ cd ~/ldlidar_ws/ldlidar_stl_sdk

# If the build folder does not exist in the ldlidar_stl_sdk directory, it needs to be created

$ mkdir build

$ cd build

$ cmake ../

$ make

¶ Run binary program

$ cd ~/ldlidar_ws/ldlidar_stl_sdk/build

$ ./ldlidar_stl <serial_number>

# eg: ./ldlidar_stl /dev/ttyUSB0

¶ Development Guide

¶ Serial communication parameters

| Sensor Model | Baud Rate | Data Bits | Stop Bits | Parity Bit | Flow Control |

|---|---|---|---|---|---|

| FHL-LD19P | 230400 | 8 | 1 | None | None |

| FHL-LD19 | 230400 | 8 | 1 | None | None |

| FHL-LD19 Plus | 921600 | 8 | 1 | None | None |

¶ Electrical parameters

| Parameter/Feature | FHL-LD19P | FHL-LD19 | FHL-LD19 Plus |

|---|---|---|---|

| Input Voltage | 4.5V - 5.5V | 4.5V - 5.5V | 4.5V - 5.5V |

| PWM Control Frequency | 0.5kHz - 1kHz | 20kHz - 50kHz | 0.5kHz - 1kHz |

| PWM High Level Voltage | 3.0V - 3.6V | 3.0V - 3.5V | 3.0V - 5.0V |

| PWM Low Level Voltage | 0V - 0.5V | 0V - 0.5V | 0.3V - 0.5V |

| PWM Duty Ratio | 0% - 100% (40% for 10Hz) | 0% - 100% (45%-55% for external control) | 0% - 100% (40% for 10Hz) |

| Starting Current | 540mA | 300mA | 540mA |

| Working Current | 290mA | 180mA | 290mA |

| Communication Interface | UART @ 230400 | UART @ 230400 | UART @ 921600 |

| UART High Level Voltage | 3.0V - 3.6V | 2.9V - 3.5V | 2.9V - 3.5V |

| UART Low Level Voltage | 0V - 0.5V | 0V - 0.4V | -0.3V - 0.4V |

| Driving Motor | BLDC (Brushless Motor) | BLDC (Brushless Motor) | BLDC (Brushless Motor) |

Notes:

Input Voltage: The recommended voltage range for powering the device.

PWM Control Frequency: The frequency range for the PWM signal used to control the motor speed.

PWM High and Low Level Voltages: The voltage levels for the PWM signal.

PWM Duty Ratio: The range of duty ratios for PWM control, with specific values for default and external control modes.

Starting Current: The initial current draw when the device starts.

Working Current**: The typical current draw during normal operation.

Communication Interface: The type and baud rate of the communication interface.

UART High and Low Level Voltages: The voltage levels for the UART communication signal.

Driving Motor: The type of motor used for the device's rotation.

¶ COMMUNICATION INTERFACE

| Product Model | Connector Type | Pin 1 (Tx) | Pin 2 (PWM) | Pin 3 (GND) | Pin 4 (P5V) |

|---|---|---|---|---|---|

| FHL-LD19P | ZH1.5T-4P 1.5mm | Data Output (0-3.6V) | Motor Ctrl (0-3.6V) | GND (0V) | Power (+4.5V-5.5V) |

| FHL-LD19 | ZH1.5T-4P 1.5mm | Data Output (0-3.5V) | Motor Ctrl (0-3.5V) | GND (0V) | Power (+4.5V-5.5V) |

| FHL-LD19 Plus | ZH1.5T-4P 1.5mm | Data Output (0-3.5V) | Motor Ctrl (0-3.3V) | GND (0V) | Power (+4.5V-5.5V) |

How to Read the Table:

Product Model: The name of the laser radar sensor.

Connector Type: The type of connector used (e.g., ZH1.5T-4P 1.5mm connector).

Pin Definitions: The function and voltage range for each pin of the connector.

¶ Instructions on Motor PWM Speed Regulation

- Supported Speed Regulation Modes

- The motor driver of LD19 has a stepless speed regulation function, supporting both internal speed control and external speed control.

- Internal Speed Control

- When the PWM pin is grounded, internal speed control is used by default, and the default speed is 10 ± 0.1Hz.

- External Speed Control

- Control Method: A square - wave signal needs to be connected to the PWM pin. The start, stop, and speed of the motor can be controlled through the duty cycle of the PWM signal.

- Trigger Conditions

- a. The input PWM frequency should be in the range of 20 - 50K(LD19 P & LD19 Plus use 0.5 ~1.5Khz), with 30K (LD19 P & LD19 Plus: 1K ) being recommended.

- b. The duty cycle should be within the interval of (45%, 55%) (excluding 45% and 55%), and the continuous input time should be at least 100ms.

Note:

When not using external speed control, the PWM pin must be grounded. - State Maintenance and Restoration: Once external speed control is triggered, it will remain in the external speed control state. The internal speed control will be restored only if the power is turned off and restarted.

- Speed Regulation Operation: After external speed control is triggered, speed regulation can be performed by adjusting the PWM duty cycle.

- Differences in Actual Speeds: Due to individual differences among motors of each product, the actual speed may vary when the duty cycle is set to a typical value. To accurately control the motor speed, closed - loop control is required based on the speed information in the received data.

With one-way communication, LD19 starts sending measurement data as soon as the

rotation is stabilized, without sending any commands.

¶ DATA PROTOCOL

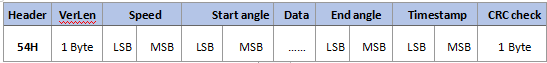

¶ Data packet format

The lidar adopts one-way communication. After stable operation, it starts to send measurement data packets without sending any commands. The measurement packet format is shown in the figure below.

| Value | Description |

|---|---|

Header |

The length is 1 Byte, and the value is fixed at 0x54, indicating the beginning of the data packet |

VerLen |

The length is 1 Byte, the upper three bits indicate the packet type, which is currently fixed at 1, and the lower five bits indicate the number of measurement points in a packet, which is currently fixed at 12, so the byte value is fixed at 0x2C; |

Speed |

The length is 2 Byte, the unit is degrees per second, indicating the speed of the lidar; |

Start angle |

The length is 2 Bytes, and the unit is 0.01 degrees, indicating the starting angle of the data packet point; |

Data |

Indicates measurement data, a measurement data length is 3 bytes, please refer to the next section for detailed analysis; |

End angle |

The length is 2 Bytes, and the unit is 0.01 degrees, indicating the end angle of the data packet point; |

Timestamp |

The length is 2 Bytes, the unit is milliseconds, and the maximum is 30000. When it reaches 30000, it will be counted again,ndicating the timestamp value of the data packet; |

CRC check |

The length is 1 Byte, obtained from the verification of all the previous data except itself. For the CRC verification method, see the following content for details; |

Data Structure Click to expand/collapse

#define POINT_PER_PACK 12

#define HEADER 0x54

typedef struct attribute ((packed)) { uint16_t distance;

uint8_t intensity;

} LidarPointStructDef;

typedef struct attribute ((packed)) {

uint8_ t header;

uint8 t ver len;

uint16_ t speed;

uint16_ t start_ _angle;

LidarPointStructDef point[POINT_ PER_ PACK];

uint16_ t end_ angle;

uint16 t timestamp;

uint8_ t crc8;

}LiDARFrameTypeDef;

The CRC check calculation method Click to expand/collapse Data Structure

static const uint8_t CrcTable[256] = {

0x00, 0x4d, 0x9a, 0xd7, 0x79, 0x34, 0xe3, 0xae, 0xf2, 0xbf, 0x68, 0x25,

0x8b, 0xc6, 0x11, 0x5c, 0xa9, 0xe4, 0x33, 0x7e, 0xd0, 0x9d, 0x4a, 0x07,

0x5b, 0x16, 0xc1, 0x8c, 0x22, 0x6f, 0xb8, 0xf5, 0x1f, 0x52, 0x85, 0xc8,

0x66, 0x2b, 0xfc, 0xb1, 0xed, 0xa0, 0x77, 0x3a, 0x94, 0xd9, 0x0e, 0x43,

0xb6, 0xfb, 0x2c, 0x61, 0xcf, 0x82, 0x55, 0x18, 0x44, 0x09, 0xde, 0x93,

0x3d, 0x70, 0xa7, 0xea, 0x3e, 0x73, 0xa4, 0xe9, 0x47, 0x0a, 0xdd, 0x90,

0xcc, 0x81, 0x56, 0x1b, 0xb5, 0xf8, 0x2f, 0x62, 0x97, 0xda, 0x0d, 0x40,

0xee, 0xa3, 0x74, 0x39, 0x65, 0x28, 0xff, 0xb2, 0x1c, 0x51, 0x86, 0xcb,

0x21, 0x6c, 0xbb, 0xf6, 0x58, 0x15, 0xc2, 0x8f, 0xd3, 0x9e, 0x49, 0x04,

0xaa, 0xe7, 0x30, 0x7d, 0x88, 0xc5, 0x12, 0x5f, 0xf1, 0xbc, 0x6b, 0x26,

0x7a, 0x37, 0xe0, 0xad, 0x03, 0x4e, 0x99, 0xd4, 0x7c, 0x31, 0xe6, 0xab,

0x05, 0x48, 0x9f, 0xd2, 0x8e, 0xc3, 0x14, 0x59, 0xf7, 0xba, 0x6d, 0x20,

0xd5, 0x98, 0x4f, 0x02, 0xac, 0xe1, 0x36, 0x7b, 0x27, 0x6a, 0xbd, 0xf0,

0x5e, 0x13, 0xc4, 0x89, 0x63, 0x2e, 0xf9, 0xb4, 0x1a, 0x57, 0x80, 0xcd,

0x91, 0xdc, 0x0b, 0x46, 0xe8, 0xa5, 0x72, 0x3f, 0xca, 0x87, 0x50, 0x1d,

0xb3, 0xfe, 0x29, 0x64, 0x38, 0x75, 0xa2, 0xef, 0x41, 0x0c, 0xdb, 0x96,

0x42, 0x0f, 0xd8, 0x95, 0x3b, 0x76, 0xa1, 0xec, 0xb0, 0xfd, 0x2a, 0x67,

0xc9, 0x84, 0x53, 0x1e, 0xeb, 0xa6, 0x71, 0x3c, 0x92, 0xdf, 0x08, 0x45,

0x19, 0x54, 0x83, 0xce, 0x60, 0x2d, 0xfa, 0xb7, 0x5d, 0x10, 0xc7, 0x8a,

0x24, 0x69, 0xbe, 0xf3, 0xaf, 0xe2, 0x35, 0x78, 0xd6, 0x9b, 0x4c, 0x01,

0xf4, 0xb9, 0x6e, 0x23, 0x8d, 0xc0, 0x17, 0x5a, 0x06, 0x4b, 0x9c, 0xd1,

0x7f, 0x32, 0xe5, 0xa8};

uint8_t CalCRC8(uint8_t *p, uint8_t len){

uint8_t crc = 0;

uint16_t i;

for (i = 0; i < len; i++){

crc = CrcTable[(crc ^ *p++) & 0xff];

}

return crc;

}

¶ Measurement data analysis

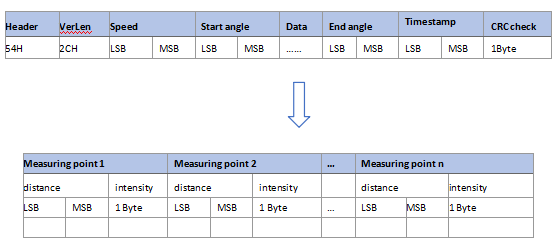

Each measurement data point consists of a 2-byte distance value and a 1-byte confidence value, as shown in the figure below.

The unit of distance value is mm. The signal intensity value reflects the light reflection intensity. The higher the intensity, the larger the signal intensity value; the lower the intensity, the smaller the signal intensity value. For a white object within 6m, the typical value of the signal strength value is around 200.

The angle value of each point is obtained by linear interpolation of the starting angle and the ending angle. The angle calculation method is as follows:

The data structure reference is as follows:

step = (end_angle – start_angle)/(len – 1);

angle = start_angle + step*i;

where len is the number of measurement points in a data packet, and the value range of i is [0,len).

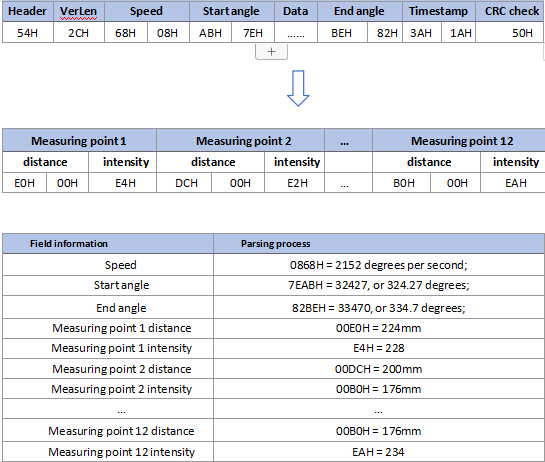

Example

Suppose we receive a piece of data as shown below.

54 2C 68 08 AB 7E E0 00 E4 DC 00 E2 D9 00 E5 D5 00 E3 D3 00 E4 D0 00 E9 CD

00 E4 CA 00 E2 C7 00 E9 C5 00 E5 C2 00 E5 C0 00 E5 BE 82 3A 1A 50

We analyze it as follows:

¶ COORDINATE SYSTEM

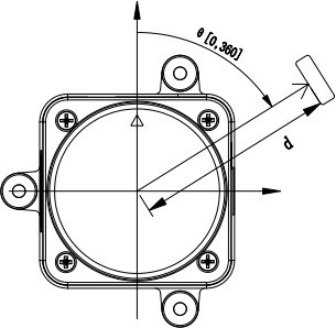

The LD19 uses a left-handed coordinate system, the rotation center is the coordinate origin, the front of the sensor is defined as the zero-degree direction, and the rotation angle increases clockwise, as shown in the figure below.

¶ FAQ

¶ Instructions for using ROS based on Raspberry Pi SBC

Please refer to the manual 《 Raspberry Pi Raspbian User manual.pdf》 for details. This manual applies to our company's product models LD06 and LD19

Raspberry Pi Raspbian User manual.pdf

¶ About us

Web:https://www.youyeetoo.com/

Forum:https://forum.youyeetoo.com/

amazon: https://www.amazon.com/youyeetoo

blog: https://youyeetoo.com/blog/

[cn web]:https://youyeetoo.cn/

aliexpress:https://smartfire.aliexpress.com/store/1100924668

Customized service:peter@youyeetoo.com